- Main navigation

- Main page

- About us

- Offerrozwiń

- Our servicesrozwiń

- Contact

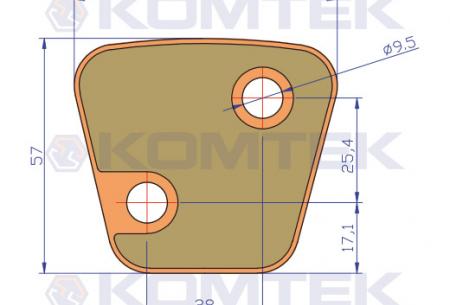

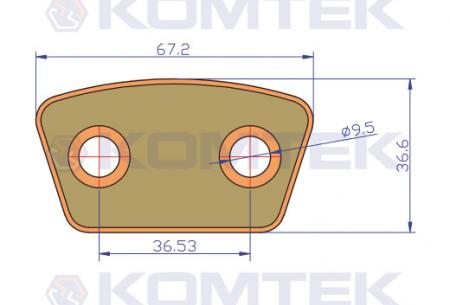

Clutch buttons

We can divide clutch buttons into two groups. They are most often used in sports cars to transfer high torque. The cluth button is capable of transferring very high torque and is often used in vehicles that have a power output of 500 - 600 hp and more. In such cars, these types of clutch buttons perform very well. They also perform very well in vehicles that are likely to get bogged down (for example, in 4x4 rallies). Because clutch button itself is produced using temperatures of about 1200 degrees Celsius it will not be damaged in extreme conditions at temperatures of about 600-800 degrees, and its lifespan is much higher. They are also used in agricultural machinery where there is very high pressure. Working in field or forest conditions and frequent use of the clutch in these harsh conditions will destroy the usual lining, while due to clutch buttons the life of the clutch is much higher. They have the advantage of being very easy to replace, it can be done without visiting a specialized workshop. The only condition is to have a strong riveting machine, because with blutch buttons semi tubular steel rivets are used, which require a lot of pressure.

For sports applications, we have Miba clutch buttons, which are manufactured in Austria. These types of clutch buttons are used for cars that race in rallies. This is a well-known brand that is very well known in the sports community.